Do you need a production line system to print QR or 2D Barcodes onto individual products, packaging or cases?

With a production line barcode printer or laser from Videojet, you can print crisp high-quality 2D Barcodes, QR Codes, logos and graphics onto nearly any surface at virtually any line speed, angle, or location on a product or package.

For ordering supplies such as ink, make-up, solvent, print ribbon or parts

For information about coding systems, quotations, making samples and scheduling a demo

For scheduling maintenance, technical questions, printer manuals and maintenance contracts

Efficient, reliable inkjets ideal for non-contact printing on almost any substrate and engineered for maximum uptime

Videojet laser marking systems are capable of marking difficult materials with accurate high-speed coding

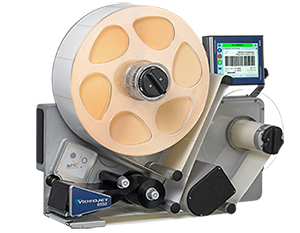

Our thermal transfer overprinters are fully electronically controlled for a high uptime. Ideal for coding flexible packaging, labels and films

Thermal inkjet printers are ideal for barcoding applications where high print quality and ease of use is paramount

With our labelling systems in the production line you can print and apply labels directly effortlessly and with absolute minimum downtime

Reduce the need of pre-printed boxes. Print high res variable data directly on the production line on cardboard boxes

Discover our range of Barcode and QR Code printing solutions and how they can help you achieve your production traceability goals.

Prevent a downtime event, with an additional 8 hours minimum protecting your production under normal operating conditions

Automate code content without the need for operator interaction with user definable message rules

Eliminate potential user errors through a Videojet SIMPLICiTY™ interface that greatly reduces operator printer interactions

Access technical experts at the touch of a button through optional VideojetConnect™ Remote Service

"We were looking for a coding solution that was simpler, faster and more reliable and Videojet supported us in achieving those goals"

Chris Byrne, Engineering Maintenance Manager, Diageo Baileys